Guide to servicing a Janome MyExcel

For the past couple of years I've been working as a sewing machine technician (yes, really, legitimately, for a shop etc) but left a month or so back. I left because I wasn't learning anything new, was a casual for the better part of two years and caught and spread covid because he couldn't tell the guy who obviously had it to stay at home, or stop coughing or sneezing etc.

Anyway, although not great in some things he's a really great technician and was an excellent teacher. Now that I'm freelancing again, I can use some of the new skills and pass them on to others. Servicing a machine is no longer just fixing it, but make it as close to new as is possible.

Mechanical Janomes are a really good choice for a secondhand machine. There's not a lot that usually goes wrong with them and if there is something it's usually quite fixable and new spare parts such as bobbin cases and feet are usually available.

I bought this machine (a MyExcel 18W) from my local e-waste recycling place. They sold it to me for very little money because someone else had brought it in not working.

How do I take it apart for servicing?

Remove the presser foot (the whole thing), then the screw the holds the needle plate on, then the bobbin case.

Flip the lid open and remove the two screws. Lift up the left side then remove the left side of the carry handle by pushing it in. The handle and top can now be removed together.

|

| Don't remove the other screws, just these |

Unscrew the side panel at the centre and the bottom (don't remove the bottom screws). It helps to also loosen the front screw closest to the top of the side panel.

Remove the two bottom panels (bottom of machine and under bobbin area).

|

| Red ones are removed, blue are loosened |

The front also needs to be removed. This is a bit less straightforward. There are two screws at the bottom (see above) to be loosened, one at the top to be loosened (which you have probably already loosened to get the side panel off), and one to be removed at the top (see next picture).

|

| Remove this, arrow points to a bar that will get in the way |

Yes the bar will be in the way in that picture, but it will be less in the way if you set the stitch length to maximum. Also set the stitch width to maximum. In the case of this machine, the stitch length was completely seized. It's unlikely to have been set to near zero before seizing, so you should be okay.

The last screw must be accessed from the right side of the machine. It's only really accessible when the pattern selector is set to buttonhole, so set your pattern to buttonhole now, look directly in and you will see a brass coloured screw quite far in. A long philips head screwdriver is perfect here. Do not remove it, you just need to loosen it a bit for the front cover to be removable.

Lift it from the bottom, manipulate the top left past the shaft as well as the other front part (which stays on), and you should be holding the front cover in your hands very soon.

Problems

So what's usually wrong with Janomes? Number one is reverse getting stuck. Janome uses grease that will harden (like a slow setting glue) over time, especially if the machine is not used. When the grease is new it's a pale yellow or just off white. The darker it is, the harder it is.

Almost all other common issues involve the same issue. Grease hardens, and whatever part of the machine it's on seizes or becomes very sticky. The couple of non grease related problems will be mentioned as I get to them.

The machine's exterior was very dirty but I didn't take a picture of it. I'm sure everyone has seen a really dirty and dusty machine before, so use your imagination. Here are a couple of photos of bits that need to be cleaned.

|

| Bottom of the machine. At the bottom is the bobbin area |

|

| Bobbin area very dirty |

|

| Top of the machine |

|

| The entire machine was like this |

Tools other than tools

You will need a toothbrush (a packet of varying levels of cleanliness would be better). Some chemicals to remove dirt - methylated spirits and mineral turpentine are ideal and a jar. An air compressor is very handy too, for drying and cleaning.

Methylated spirits is also fantastic for cleaning Janome plastic. Just don't get it on the lettering. Sometimes it comes straight off too.

There is a nylon brush commonly used by sewing machine mechanics that I use quite a lot. You won't be able to get to everything with a toothbrush because they're only one shape. If you have to clean something that isn't on the side of wherever you're poking, a toothbrush won't get to it.

Some modern grease, preferably with teflon, and some sewing machine oil.

Some absorbent rags.

You will of course need actual tools as well. A basic set of screwdrivers and an allen key will be necessary. A set of small files will be useful for filing out damage if required.

Inspecting parts

Look at the black bobbin case. If there is damage to where the thread gets taken around by the hook, you need to determine whether it can be fixed. Fixing it means making it smooth again. Any burr on the bobbin case will snag the thread, so you must attend to it. If you don't have small files, you can use emery paper but it's more difficult.

|

| Sometimes this area has needle damage |

This one is clearly perfectly fine so I didn't need to do anything.

Next, check the needle plate for damage.

|

| The damage is obvious |

This time I wasn't so lucky. Clearly a needle has struck the needle plate several times. The top damage here is first to be filed flat.

|

| Now it's very smooth |

Okay, you can see that the area the needle passes through is also damaged, so inspect it.

|

| Again, the damage is obvious |

The same issue arises if you don't file this out. Thread will snag and you will get unsatisfactory stitching.

|

| File out the damage so it's smooth |

It took just a minute or two to fix this, but if you don't it will definitely cause a problem.

Next thing to check is that the upper timing wheel is tight. To do this you need to remove the bobbin winder. Take a picture of it before you remove it.

|

| Tighten the TWO allen screws |

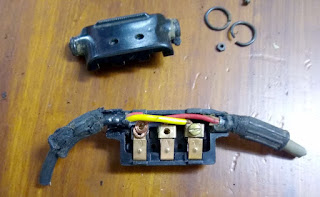

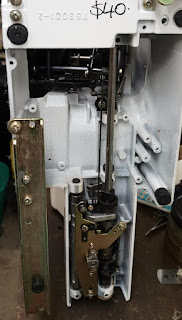

Next, look at the side. I like to remove the motor and check the bearings, but this model is usually fine. However, the connection block where the plug goes in is often damaged. I really wanted to go to town on this machine so I removed the motor from the machine completely. Partly to make it easier to photograph the stuck parts. If you aren't planning to remove the motor, at least remove the toothed drive belt. This is quite easy: Just slip it towards you at the top and it slides off the hand wheel a bit at a time.

Next remove the hand wheel: Pry off the cover, and unscrew it. The inside will be covered in heavier machine grease but unless it's solid, I leave it alone.

|

| If this slips, you will have lots more work |

Clip the two sides of the belt together (to maintain tension), and remove the tensioner bracket then remove the tensioner wheel from the bracket (there's a circlip, be careful when removing this of course). The wheel is usually caked in grease, so clean it all off as well as any parts of rubber belt that may have transferred to it. Once dry, just put a little oil on the cleaned shaft and put it all back on again, including the circlip. Make the tension so it's not pulling on the motor. The toothed belt means it doesn't have to be tight. If it is tight, it will damage the motor.

Don't replace the hand wheel yet, or the motor if you have removed it.

Now get the reverse working. The following photo shows the area you need to be working on. It's at the bottom of the machine.

|

| Reverse gets stuck here |

You need to remove the circlip, remove the washer underneath, remove the spring.

Lift the mechanism off the slider on the shaft, and unhook the connecting rod that you can see going off to the right. Now you can remove the whole reverse mechanism. Clean the part it pivots on (shown by the arrow) as well as the mechanism part that comes in contact with it. You also need to ensure that the slider can slide freely. Clean either side of it with the solution. Remove all traces of the yellow grease (I took the following picture after starting this). So 1 and 2 are the reverse, and 3 is part of the feed. Also clean the other end of that shaft.

|

| Some places to clean. |

If you were just here to find out how to fix the reverse that's it, but for a service, remove all of the dirt and grease on the rest of the bobbin mechanism. Position 2 requires a small smear of grease.

|

| Grease these spots |

You don't need to overdo the grease. I like teflon grease (and oil) because they tend to resist the effects of gravity better than the other stuff.

So now you have attended to the bottom and side of your machine.

The top is mostly easy but there's usually sticky grease on this shaft.

|

| You know what to do |

Remove the screw and bracket, and the shaft should now be movable. Dissolve the grease at the top and at the bottom.

Remove the gold coloured bracket that the light is mounted onto for better access to the needlebar and presser foot and clean with solvent then dry and re-oil.

Replace the bracket.

There's some more grease around the top. Remove as much as you see and replace with new.

|

| Remove the grease first |

Now it's time for the difficult part. Not for any reason other than some of it is difficult to get at. Move the stitch width lever (if you can), and you should see the front two discs turn. If you can't move it (this one was seized) I can assure you it is supposed to move separate to the rest of those plastic parts.

If it is not moving easily, insert a small flat bladed screwdriver between the moving and static parts and brush in some of solvent. Here is a picture of it. I know I wouldn't be keen without one.

|

| Notice the grease is gone now |

If yours is also seized, it's just that the grease has once again set and glued the discs together. Clean all the grease away (it took several applications with this machine) and keep at the solvent between the discs. The lever will start to move freely. Keep it going, sometimes this takes a good half hour of work to un-seize.

Once it's freed up it isn't usually the end of the story. The rest of that mechanism is also invariably also seized or at least sticky. Brush away as much as you can see. You will need as much access as possible, which is why I said not to replace the hand wheel, belt or motor.

In particular, this shaft needs to be cleaned thoroughly. The separate parts of it need to be able to move easily.

|

| Move the pattern selector to move this |

Move the pattern selector to get maximum access to the shaft, and apply the solvent both ends as well. Once the parts can move freely, oil it (I don't grease this).

When you change the stitch length it should be pretty easy but you should see the feed dog moving. If it isn't moving, then the shaft that controls it is still stuck and you need to keep working on it until it's working properly.

When you move the pattern selector and the stitch width lever, you should see the needle bar move left and right. If it's sticky, you need to keep working on it.

Getting these parts free is the hardest part of this job. Once you have done it, give yourself a big pat on the back. Its neither quick nor easy to do this.

Reassembly of your machine should take a while too. This is because before putting any external plastic back on, it must be cleaned. This is possibly the strongest lesson I learned from the shop. The machine must also be made to look as close to new as possible. Before putting a panel back on, clean all the dirt off. If the machine is yours, this should make you feel much better about using it. Use methylated spirits or cleaning solution. The latter is safer for the decals.

Put back the motor if you removed it, and the bobbin winder, power socket etc.

Put the front on first. Make sure both controls are set all the way to the right, as well as the levers, otherwise they won't enter and you'll have to take the cover off again to fix this. Once it's back on, don't tighten the top right screw just yet.

Replace the side cover. Put the screw back, tighten the screws at the bottom, then tighten the front cover screw. Replace the pattern selector knob.

Replace the front cover screws and tighten the ones you didn't remove, including the ones at the bottom. Make sure the tension release is connected.

Replace the bottom bobbin area cover then the bottom cover.

Replace the top cover and carry handle at the same time.

Replace bobbin case, needle plate, bobbin and bobbin cover.

Hopefully your machine should be working perfectly now. If there's still something wrong, you're more likely to learn from it if you have to go back and do it all again.

Please give me feedback. If there's something wrong with these instructions I'd like to know. I'm writing all of this from memory, which at my age isn't all that great.